How to generate digital data for an improved glass development?

Development of new technical glasses

Glass has played a significant role in the lives of humans for over three millennia: from jewelery and ritual objects, kitchen or table ware and windows to emerging applications such as bioactive implants and energy materials. However, despite the well-established history of this material, very few of conceivable glass compositions have been discovered and explored to date. The production or introduction of new multi-functional glasses requires a long and expensive period of development.

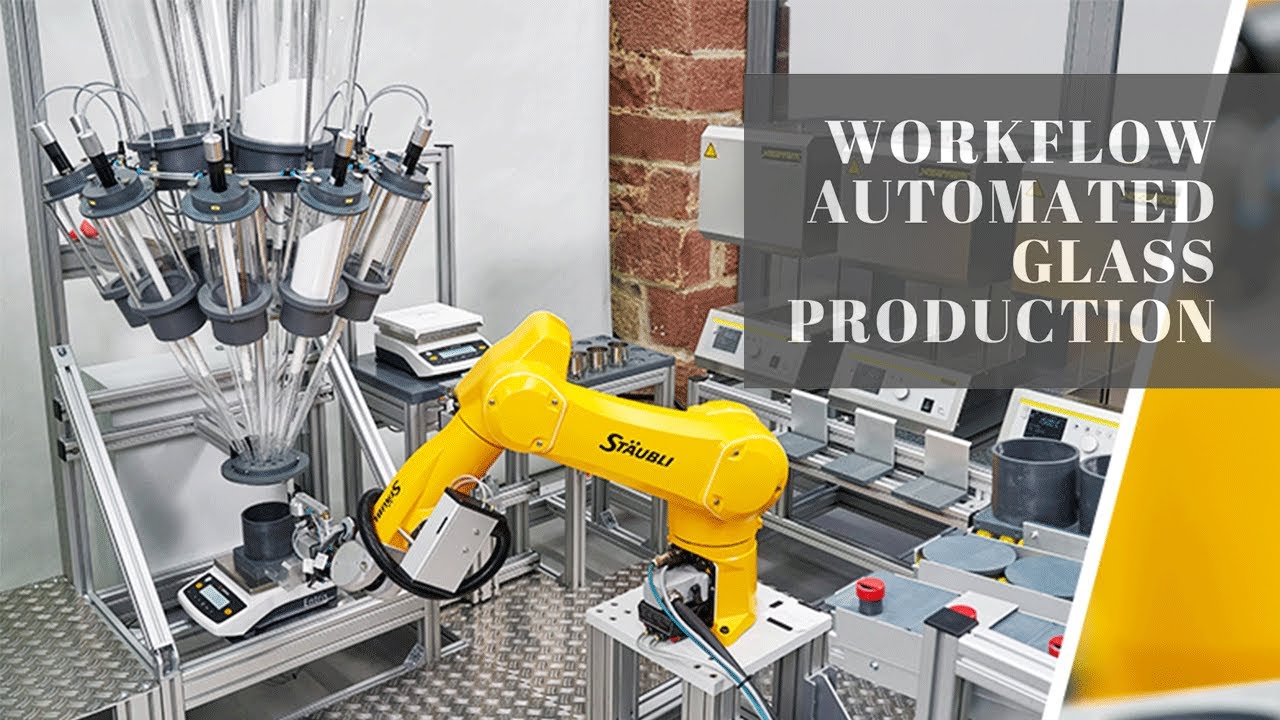

To overcome this time-consuming process, Fraunhofer ISC has developed a new generation of automated glass screening, a robot-controlled process line called »Glass Screening Apparatus«. It automatically handles all the necessary process steps automatically to develop new glass compositions using digital interfaces to transfer all data to a digital workflow.

The automation approach

This process automation enables a methodical development of glass systems through high reproducibility and digital process control. It generates all necessary data and leads to process optimization. Automatically produced glass samples deliver large quantities of data relating, for example, to Young’s modulus, solubility and glass-transition temperature, which is a fundamental requirement to enhance and collect the data based knowledge of glass.